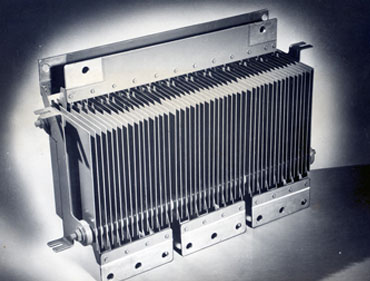

Selenium Rectifier

The H and W series are the result of continuous research and development programme aimed at reliable, low-cost, compact selenium rectifier elements and stacks. High standard of quality are further insured by Westing house plants & machinery and the expert technical know-how available at Insel Rectifiers.

The aluminium based selenium rectifier elements are manufactured by an improved, closely controlled vaccum deposition process. This new process ensure stable, non- ageing, low loss characteristics permitting higher current density operation while maintaining a reliability standard which has been a by in the selenium rectifier field for over thirty years.

IRI selenium rectifier ’s elements are available in two categories, series H & w. Both series are available in Voltage grades up to 36 volts.

Our Products

| H | O | G | LA | 06 | B | 01 |

| H | O | G | LA | 06 | B | 01 |

| Rectifiers Series | Max. RMS input Voltage per series element | Element Code | Mechanical structure/ spacing | Number of series elements per arm | Circuit Arrangement | Number of parallel path per arm |

| H— | 0—22 | C | L | 2Digits | Single Phase | 2 Digits |

| Normal | D | LA | A-Half wave | |||

| Current | E | B- Brige –ve Outer | ||||

| Density | 1—30 | G | C-Centretap –veCommon | |||

| K | ||||||

| M | N-Centretap | |||||

| Q | -ve common | |||||

| 2—36 | R | D-Voltage doubler | ||||

| W- Higher | Y | Three Phase | ||||

| Current Density | S | G- bridge | ||||

| 3—25 | N | E- Halfwave +ve Outer | ||||

| T | R- Half Bridge –ve Outer | |||||

| P | S– Hexaphase | |||||

| 4– 33 |

CURRENT RATING OF IRI ELEMENTS IN STACKS

| RIES | GRADE | Elements | Active Area in Sq.com | Mech. Structure | Maximum recom- mended elements in stack | Single Phase | 3 Phase Bridge & Half Wave | Hexa Phase | ||

Dim.In mm | Half Wave | Bridge | ||||||||

| ‘H’ SERIES | IN 0,1,2,3, &,4 Volatage grades | C D E F G K M Q R Y S N T P | 17×17 23X23 36X23 36X36 50X50 76X50 76X76 100Z62 102X76 100×83 100×100 152×76 152×100 305×76 | 1.9 4.0 6.75 11 23 35 50 62 80 74 90 107 152 221 | L L LA L L L LA L LA L LA L LA L LA L LA L LA L LA L LA L LA | 40 40 40 40 40 40 32 40 32 40 32 40 32 42 32 42 32 42 32 42 32 42 32 42 32 | 0.08 0.23 0.30 0.52 0.65 1.10 1.35 1.65 2.02 2.75 3.00 3.00 3.30 3.50 4.00 3.75 4.50 4.00 5.00 5.50 6.00 6.00 7.50 10.25 12.30 | 0.16 0.46 0.60 1.04 1.35 2.20 2.50 3.30 3.75 5.50 6.00 6.00 6.60 7.00 8.00 7.50 9.00 8.00 10.00 11.00 12.00 12.00 15.00 20.50 24.60 | 0.24 0.51 0.75 1.38 1.75 2.85 3.15 4.27 4.82 7.15 8.50 8.00 8.80 10.70 12.00 11.25 13.50 12.00 15.00 14.30 18.00 18.00 22.00 26.65 35.00 | 0.35 1.02 1.50 2.76 3.50 5.70 6.30 8.55 9.45 14.30 17.10 16.00 18.00 21.45 24.00 22.50 27.00 24.00 30.00 28.60 34.00 36.00 44.00 53.20 63.85 |

Note:

1. For ‘W’ Series add 40% to the current rating given above for ‘H’ Series.

2. The rating above are at an ambient temperature of 450 degree C

| Circuit | Formula | AC\DC Current Ratio (1) | Ripple Percent(2) | n (Approx) |

| SINGLE PHASE | ||||

| Half Wave | VL= 2.22 | 2.22E | ||

Ve ( E+nVf)1.57121 Centre- tapVL= 2.22 2.22

Ve (E=2nVf)0.8048 BridgeVL= 1.11 1.11E

Ve ( E=4nvf)1.12548 THREE PHASE Half WaveVL= 1.48 1.48E

Ve ( E+3nVf)0.6018.3 BridgeVL= 0.742 0.742E

Ve (E+6nVf)0.804.2

VL = on – load a.c. input voltage ( total secondary voltage for single phase center – tap line- to line for three phase half wave and bridge)

E = mean d.c. output voltage .

Vf = mean element forward voltage drop.

N = number of series elements .

Ve = Voltage of plate

| (1) = | a.c. input curre d.c. output current |

| (2) = | a.c. ripple voltage – r.m.s. x 100 mean d.c. output voltage |

| PlateType | Mechstructure | Fig.Ref. | Width(W)mm | Height(W)mm | F.L(Cx2) +PXN | Pitch(P)mm | SpindleDia(D) | EProjections on both sides mm |

| C D E F G K M Q R Y S N T P | L L LA L L L LA L LA L LA L LA L LA L LA L LA L LA L LA L LA L | 6 6 6 4 6 2 2 4 4 2 2 5 5 5 5 5 5 2 2 4 4 5 5 1 1 | 17 23 23 36 36 50 50 50 50 76 76 62 62 76 76 83 83 100 100 152 152 100 100 381 381 | 32 35 35 35 48 68 68 100 100 100 100 122 122 122 122 122 122 122 122 100 100 185 185 100 10 | 32+PxN 32+PxN 32+PxN 32+PxN 32+PxN 20+PxN 20+PxN 20+PxN 20+PxN 45+PxN 45+PxN 45+PxN 45+PxN 45+PxN 45+PxN 45+PxN 45+PxN 45+PxN 45+PxN 45+PxN 45+PxN 45+PxN 45+PxN 51+PxN 51+PxN | 2.5 3. 35 5.8 5.8 7.1 7.0 8.5 7.0 8.5 9.9 12.2 12.2 17.3 9.9 12.2 9.9 12.2 12.2 17.3 12.2 17.3 12.2 17.3 9.9 12.2 | 3/16 3\16 3\16 3\16 3\16 1/4 1/4 1/4 1/4 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 | 10 10 10 10 10 15 15 15 15 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 20 |

N = Number of plates in stack

F.L. = Fixing Length

C = End assembly length

P = Plate Distance

Rectifiers with 4 or less than 4 plates shall be screw / bolt mounted

Setting the Standard in Selenium Rectifier

ManufacturingInsel Rectifiers takes pride in its unwavering commitment to excellence as a leading Selenium Rectifier manufacturer. Renowned for crafting precision-engineered components, we stand at the forefront of the industry, setting benchmarks for quality and reliability in Selenium Rectifiers and Selenium Bridge Rectifiers.

Precision in Selenium Rectifier Manufacturing

At Insel Rectifiers, we specialize in the art of Selenium Rectifier manufacturing. Our commitment to precision engineering ensures that every Selenium Rectifier and Selenium Bridge Rectifier we produce adheres to the highest industry standards. These components play a pivotal role in converting alternating current (AC) into direct current (DC) with optimal efficiency.

Crafting Excellence: Selenium Rectifiers by Insel Retifiers

As a distinguished Selenium Rectifier manufacturer, we understand the critical role these components play in various applications. Insel Rectifiers excels in crafting Selenium Rectifiers that go beyond functionality; they embody precision, durability, and reliability. Our commitment to excellence is reflected in every product, setting a standard that our competitors strive to match.

Selenium Bridge Rectifiers: Elevating Efficiency

Insel Rectifiers extends its expertise to Selenium Bridge Rectifiers, contributing to seamless power conversion. These rectifiers play a vital role in diverse applications, ensuring the smooth and efficient transformation of AC to DC. With Insel, experience the efficiency and reliability of Selenium Bridge Rectifiers designed for optimal performance.

Your Trusted Selenium Rectifier Supplier

Insel Rectifiers is not just a manufacturer; we are your trusted partner as a Selenium Rectifier supplier. Our commitment extends beyond crafting exceptional components to providing reliable solutions tailored to meet your specific requirements. As your dedicated supplier, we prioritize customer satisfaction, ensuring prompt and efficient service.

Why Choose Insel Rectifiers?

Expertise: Insel Rectifiers brings decades of expertise as a Selenium Rectifier manufacturer.

Quality Assurance: Rigorous testing ensures that our Selenium Rectifiers meet and exceed industry standards.

Customer-Centric Approach: Insel Rectifiers is committed to delivering tailored solutions that meet your unique needs.

Conclusion

Come and explore the epitome of excellence in Selenium Rectifier manufacturing with Insel Rectifiers. Our dedication to precision, durability, and reliability distinguishes us in the industry. Opt for Insel Rectifiers when you seek Selenium Rectifiers that not only meet but surpass your expectations, delivering solutions that enhance the efficiency of your applications.